In 2019, the market for Premade Pouch has exceeded 9 billion USD, It is still growing at a rate of 4% every year. Maybe you have found that the goods on the supermarket shelves are beginning to have more and more exquisite and practical packaging bags. In fact, most of them are premade pouch. Premade pouch occupies a large part of the packaging bag market.

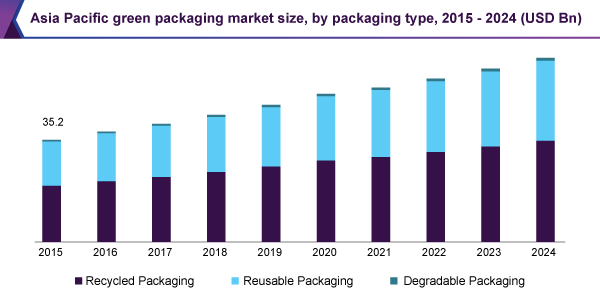

There are many reasons why premade pouch can occupy the market. The main reason is that more and more people have met their basic needs for food and clothing. After casual snacks began to rise, consumers began to pursue products with exquisite appearance and good consumer usability. In addition, due to the maturity of packaging automation, the overall cost of the premade pouch packaging line has been reduced. The rise of the concept of green and environmental protection makes the company more inclined to use premade pouch that saves materials and waste to cater to the public’s preferences.

For our research on green packaging, you can read The Future of the Packaging Industry —— Green Package

Productive Material

Although the types of packaging are dizzying, the materials of the packaging bags are similar. Most companies on the market use plastic as materials for cost and performance considerations. Sometimes companies use paper as materials to highlight their products’ organic and natural characteristics. A small number of companies use metal materials (not Complete metal, metal is only used as a plating), which makes it look different, but it also greatly increases the cost.

Market

The largest application market of the premade pouch is the food industry, followed by medicine, agriculture, cosmetics, etc. According to geographical division, Europe and Asia are the two largest markets. The European market accounts for about 25% of the global market of premade pouch due to the long development time of the industry and high penetration rate. In Asia, due to its large population, and many regions also have complete industrial chains, its market accounts for about 30% of the global market. The industry generally believes that Southeast Asia has great potential in the future growth of the global premade pouch market. According to the closure type of packaging, about 45% of the overall market uses tear notch, about 35% uses spout, and about 15% uses zipper. The remaining 5% is other types.

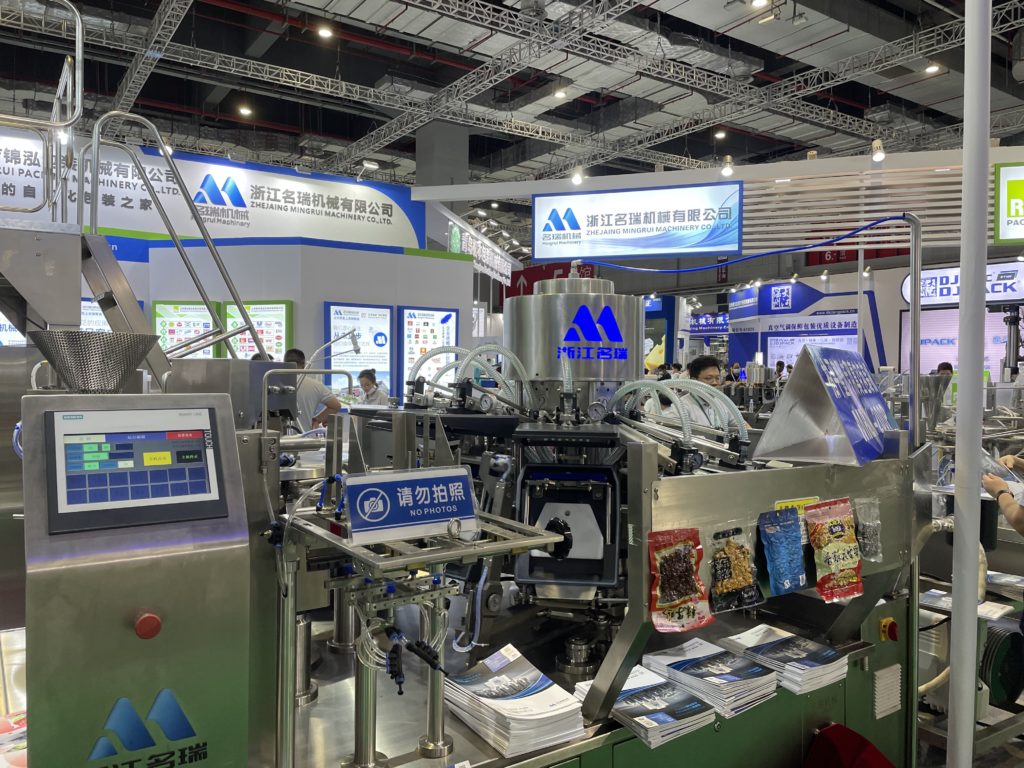

The current packaging machine market has not yet seen a large-scale monopoly manufacturer, but many small and medium-sized manufacturers are forming a series of end-user-based alliances through acquisitions and partnerships. This’s because more and more complex packaging methods involve more and more components so that this industry more and more complex. Many companies use cooperative mergers and acquisitions to stabilize supply and control prices, resulting in the trend of oligopoly.

Type

As the market of premade bags expands, its demand is also in an increasing trend. Premade bags are the most widely used bag type in packaging machinery. Most of the bags that can be found in daily life are premade pouches. Subdivide the premade bag, there can be many different names.

Stand-Up Pouch

One of the biggest advantages and main features of the stand-up pouch is that the pouch can stand. Any bag that can stand can be classified into a stand-up pouch. The bags standing on the merchandise shelves can be more easily selected and noticed by consumers, the external conditions of the stand-up pouch and its uniqueness in product printing and promotion, merchants and enterprises can carry out product promotion printing or corporate culture promotion on the front, back and bottom of the stand-up pouch according to actual needs. Stand-up pouches are widely used in the packaging of granules, powdered food, and beverages. This packaging form makes it stand out among many ordinary packaging bags. On a global scale, people’s demand for stand-up pouch is also increasing day by day.

Stand-up pouch is a general designation, it in the form of many, the most common is with zipper spout and tear notch. They are all reusable. In North America and Europe, the green environmental protection concept more thorough popular feeling, so there is a higher demand for reusable prefabricated bags. People’s market demand for ordinary sealed bags is also increasing year by year.

Manufacturers are increasingly choosing biodegradable and recyclable materials to make bags. With the gradual development of urbanization and industrialization, people realize that environmental protection is imminent. With the improvement of living standards and the growth of per capita disposable income, reusable packaging is more and more popular among people. In various industries, the advantages of premade bags have been discovered by people, which is also an important reason for the gradual expansion of the premade pouch market. In the Asia-Pacific region, especially China and India, the demand for premade bags is gradually increasing.

Pillow Pouch

Pillow pouches and stand-up pouches have always been the two giants in the global flexible packaging market, occupying a major position in the flexible packaging market, and pillow pouches account for slightly higher proportions in this market than stand up pouches. The market for pillow pouches has always been large, and many products around us are also packaged in pillow-shaped packaging.

Pillow pouches can pack a lot of objects, liquids, powders, and solids can all be packed in pillow pouches. It can be applied in a wide range of fields, such as the food industry, and pharmaceutical industry. Common products around us can be packed in pillow-shaped pouches.

Europe and North America produce more PET materials, so there are mature pillow bag packaging markets in Europe and North America. In recent years, the growth rate of the pillow bag market in the Asia Pacific region is higher than that in other regions. In China and India, the pillow bag market has been showing steady and rapid growth. This is mainly due to the increasing tendency of consumers in these two regions to use convenient and attractive packaging, rich and colorful printing, and easy-to-use packaging makes pillow bag packaging more and more popular in these two countries. Of course, the low price is also a factor that cannot be ignored.

Pillow pouches are sealed at the bottom, top, and back, which reduces the use of packaging materials compared with other packaging forms.

Stick pouch is a special form of pillow pouch. This is a longer and narrower pillow pouch, shaped like a stick, which is often used to pack small items such as instant coffee and brewed milk tea.

Spout Pouch

Spout pouch, as the name shows, is a bag with a spout. Also called fitment pouch, because the spout part usually needs to be made separately and used in conjunction with the bag body.

Spout pouches are widely used in liquid packaging. Compared with glass bottles and plastic bottles, bags with spouts save more space in transportation and storage, can transport a larger number of bags. Because of the softness of the bag, it also reduces the possibility of breakage of the outer packaging during transportation. For example, glass bottles must be shatter-proof during transportation, which increases the cost of packaging and transportation. As for the spout pouch, it can be said that there is no such problem in this regard.

Spout bags are more popular when packaging liquids with weaker fluidity. When packaging liquid materials such as ketchup and mayonnaise in a bottle, when the remaining amount in the bottle is reduced, the remaining sauce is always not well and completely taken out. In the long run, this will inevitably cause food waste. At a time when Green Action is becoming more and more popular, such a phenomenon is obviously not what we want to see. The body of the spout bag is made of recyclable materials, and the body is soft and easy to squeeze so that 99.5% of the material in the bag can be taken out. In addition, compared with ordinary plastic bottles, bag packaging uses less plastic, which means that bag packaging can be more environmentally friendly.

Nowadays, more and more liquid beverages are packaged in spout bags. Because compare with bottle, the spout pouch is occupied less space, and it is more suitable for people to carry around.

In the global market for spout bags, North America and the Asia-Pacific region account for the two most important parts. They are the two largest markets for spout bags, followed by Europe.

Paper Pouch

Looking around life, more and more paper packaging appears around us. Fast-food restaurants such as McDonald’s and Burger King have long used paper to package food. Some roasted nuts and roasted foods also use paper packaging. Bakeries also choose to use paper packaging to store freshly baked bread. The application range of paper packaging is gradually expanding, and the advantages are gradually being known. More people choose to use paper packaging instead of plastic packaging bags. Environmental protection and degradability is an important breakthrough in the form of packaging.

Paper pouch is directly made from wood, so it is also more expensive. The increase in cost and the increase in profit cannot form a good balance and coordination. It is for this reason that paper packaging is not as widely used as plastic packaging.

Kraft pouches are an important category in paper packaging. There are many types of Kraft paper, including natural Kraft paper, colored Kraft paper, printed Kraft paper, and so on.

Kraft paper pouches are different from the paper packaging of food in fast-food restaurants. Kraft paper has better strength and durability and is more suitable for packaging some items with a certain weight. The increase in strength and durability has increased the number of repeated uses of kraft paper, which is more in line with the requirements of environmental protection. Like ordinary paper packaging, kraft paper is made of biodegradable material, which provides packaging manufacturers with unparalleled opportunities in the food, beverage, and pharmaceutical industries. The increase in tear resistance allows manufacturers to increase their interests, and make consumers feel better.

The Asia-Pacific region is the largest user of Kraft paper pouch and has always occupied a dominant position in the Kraft paper pouch market. Japan, China, and India are the three main markets. In recent years, the demand for Kraft paper in Europe and the United States has also increased significantly. Driven by regulations and urbanization, people’s awareness of environmental protection has increased. The U.S. government has implemented more stringent regulations on environmental protection. In Europe, the government has initiated many environmental protection programs, which have increased the use of Kraft paper year by year.

Flat Bottom Pouch

The biggest distinction between the flat bottom pouch and other stand-up pouch is the bottom of the flat pouch is a flat surface. This design allows the bag to stand more stable.

For food manufacturers, the bottom design of the flat bottom pouch allows more items to be placed in the pouch, and this design is more cost-effective. For pouch manufacturers, compared with ordinary standing pouches, the flat-bottom design saves more raw materials for manufacturing.

The width of the flat bottom pouch is narrower than most ordinary standing pouches on the market. Therefore, when flat bottom pouches and other stand-up pouches are placed on the shelf together with the same capacity, the flat bottom pouches will always be higher. On the same shelf, the number of flat bottom pouches that can be placed is relatively large.

The design of flat bottom pouch has an advantage that other pouches don’t have: the flat bottom pouch has 5 planes that can be printed, which can make the type of flat bottom pouch more plentiful. Another reason that flat-bottom pouches are so attractive to manufacturers is that the open mouth of the flat-bottom pouches makes it easier to fill products. The larger receiving opening allows materials to enter the bag more quickly and conveniently, which is an advantage that other types of bags are difficult to achieve.

On the whole, when customers are faced with choosing a product in front of the shelf, the flat bottom pouch has more chosen by customers because of higher and richer forms. The flat-bottom pouch is square and more beautiful, so it is always selected by the high-end food industry. However, the cost of manufacturing flat-bottomed bags is relatively high.

Flat bottom pouches are mostly made of plastic or paper and are used in food and pharmaceutical industries. North America is the largest market for flat bottom pouches and will continue to maintain a relatively large growth rate for a period of time in the future. The utilization rate of flat bottom pouches in the Asia-Pacific region is also relatively high. In the future, the Asia-Pacific region will continue to grow at a rate higher than the average growth rate.

Gusseted Pouch

The appearance of gusseted bags is somewhat similar to that of flat bottom pouches, and they have certain similarities. The difference is that the connection of the gusset pouch will be stronger. Therefore, the gusseted pouch can bear more weight. The bottom of the gusseted pouch is also flat, like a flat bottom pouch, the gusseted pouch can also contain enough materials and can be placed on the shelf steadily.

Gusseted pouches are mainly made of plastic or paper with plastic film. Both ordinary packaging and vacuum packaging are suitable for gusseted pouches. Gusseted pouches are also suitable for the installation of some dry materials, such as coffee beans, tea, rice, and other baked products.

Gusseted pouch, as a pouch type, can also be divided into two types: side gusseted pouch and bottom gusseted pouch.

We simply understanding that the side gusseted pouch is to reinforce the side corners of the package, and the bottom gusset pouch is to reinforce the bottom of the pouch. One of the biggest differences is that when we disassemble the pouch, we will find that the side of the side gusseted pouch will present a shape similar to a triangle, while the side of the bottom gusseted pouch will have a shape similar to a quadrilateral. In other words, when the manufacturer wants to enrich the packaging style, the side gusseted pouch can have 5 sides for the manufacturer to create, while the bottom gusseted pouch has only 4 sides. Due to these characteristics of the bottom gusseted pouch, it will be larger than the side gusseted pouch.

Gusseted pouches are also called quad seal pouch or box pouch in some cases.

Sachet Bag

Sachet bag is a general term for a kind of simple small bag, at present, disposable tea bags, instant coffee, shampoo, cosmetic samples, etc. are all packaged in sachet bag. This form takes advantage of people’s consumer psychology, especially in countries and regions with lower income levels. Low income makes it impossible for people to afford higher-priced items, and sachet pouch is rapidly gaining a certain advantage in the packaging market of these countries and regions due to its advantages of small quantity and low price.

In Egypt, 20% of the people live below the poverty line, and people are more inclined to choose a small-sized product. Local retailers are seizing this consumption characteristic and seizing the opportunity to open the sachet pouch market in the local area.

Plastic is the most common manufacturing material in sachet pouch. The weight, low price, compression resistance, and tensile strength of plastic are all good choices for the manufacture of sachet pouch. Plastics can also be printed to enrich the shape of the packaging so that more consumers can choose it.

Zipper Pouch

A reusable zipper is provided at the sealing of the packaging bag. Consumers can seal multiple times during use. At the same time, the zipper can also lock the materials in the packaging. Because of the moisture-proof and waterproof functions of zipper pouches, they are becoming more and more popular all over the world. At present, the largest contribution to the global zipper pouch market is the North American market. It is expected that in the next few years, Europe and the Asia-Pacific region will also make a significant contribution to the zipper pouch market. In China and India, where the food packaging market is becoming stronger, the demand for zipper pouch is increasing due to the influence of environmental protection concepts. In Europe, people who have a higher standard for food safety and hygiene are affected by relevant environmental protection policies and regulations. Driven by the green and healthy market, the demand for zipper bags will also have a higher level in the next ten years.

There is also a special form of the zipper pouch, which is the Inno-Lok bag. The difference is that the zipper installation position of the Inno-Lok bag is located inside the bag. When the user opens the zipper, he generally needs to tear off the wrapping paper on the outside of the zipper according to the prompt on the outside of the packaging bag. Inno-Lok bags are generally larger in volume and size.

Three/Four Side Seal Pouch

The three side seal pouch is simple to manufacture and has various forms. The size and capacity can be customized according to the different requirements of customers. At the same time, three side seal pouches are used for printing and marketing that conforms to the public’s aesthetics. As a result, more and more people use three side seal pouches. North America and Western Europe have always been the main market for three side seal pouches. The utilization rate of three side seal in the Asia-Pacific market, dominated by China and India, is also increasing.

Four side seal pouches are used more in the food and personal care fields. In the beverage manufacturing industry, the market valuation of four side seal pouches is expected to reach 5.3 billion U.S. dollars in 2024. The growth rate of the four side seal pouch market in the personal care industry is expected to exceed 7% in 2024. Consumers and product manufacturers continue to increase their demand for four side seal pouches, which has driven the growth of four side seal pouches.

The growth of the tourism industry has increased the demand for food in small bags. Four side seal pouches have replaced the rigid packaging of traditional cans and have become a new form of travel for many people.

Degassing Valve Pouch

The degassing valve pouch is a pouch that has a small application range but can play an important role in a specific field.

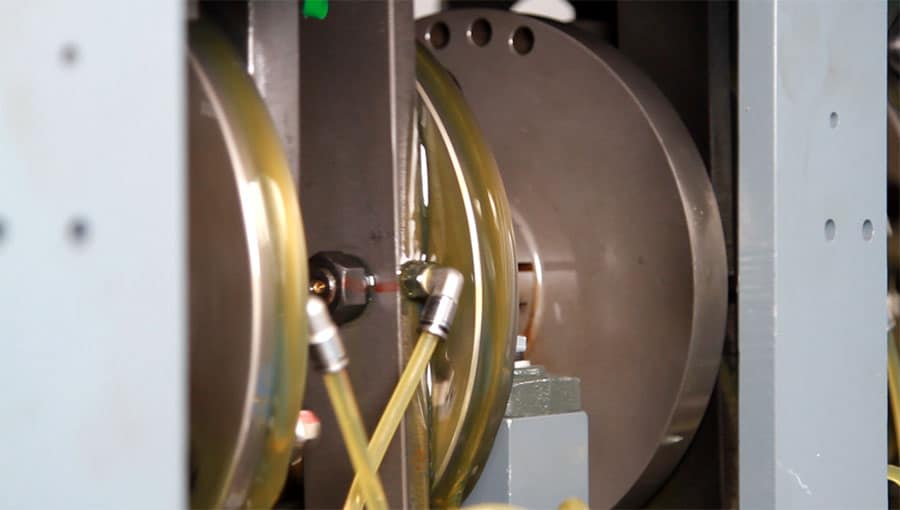

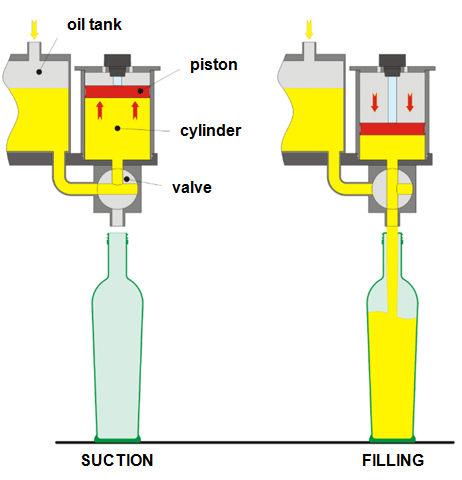

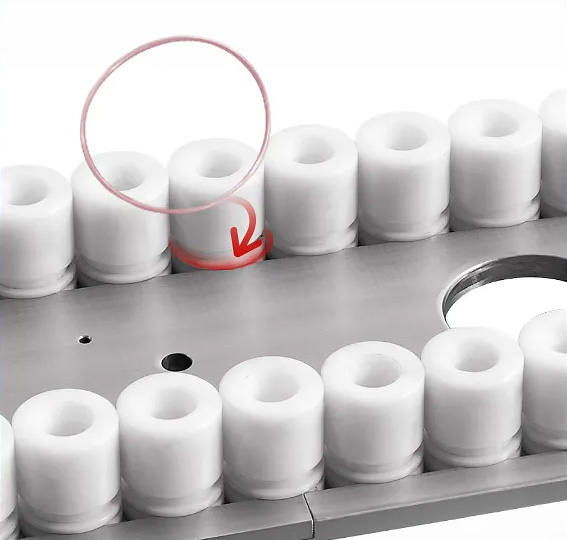

The degassing valve pouch was originally designed for coffee packaging. The roasted coffee beans will generate a lot of gas in the confined space. The design of the de-air valve is to keep the pressure inside the bag approximately the same and at the same time isolate the air from outside the bag to ensure the freshness of the coffee beans in the bag.

When the material in the pouch produce gas, the air pressure inside the bag will be slightly higher than that outside the bag. At this time, the de-air valve will be opened to discharge the gas in the bag. Don’t worry about the gas outside the bag entering the bag when the degas valve is opened. The de-air valve is a one-way exhaust port, and the gas can only go out but not in.

Now the degassing valve bag is mainly used in coffee, pet food, and other items that are prone to fermentation to produce gas.

Twin Bag

At present, there are not many twin bags made of plastic film. Twin bags are more often made of canvas in our daily lives. With the improvement of living standards, people began to have higher requirements for hygiene. As a result, twin bags made of plastic film have gradually increased. Now, some of the facial masks launched on the market begin to separate the facial mask essence and the facial mask paper to seal the two objects used at the same time in two different spaces; in the food industry, the food and the sauce are also beginning to separate of packed twin bags. Merchants claim that this kind of packaging will be more hygienic. The two bags are connected together, if it is not deliberately removed, the two bags will not be easily separated. This design is also for the convenience of consumers to carry.

Flat pouch

Flat pouches have very little space and can hold a limited number of items. Flat pouches are commonly used as preservatives in food packaging.

Of course, it is not to say that the size of the flat pouch is as small as the preservative packaging. Flat pouches can also pack small items. For example, product samples, etc. In terms of marketing, the flat pouch has two sides that can be printed, which is equivalent to the entire visible side of the flat pouch that can be used for promotion.

Doypack Pouch

Doypack Pouch refers to a standard standing bag, also known as Doyen Pouch. When the bottom is sealed in a “K” shape, it is also called K-seal pouch. In fact, Doypack Pouch is a trademark registered by an early French company, and its name is taken from DOYen PACKaging.

Double Doy pouch is a newer bag. The bag can stand on the top and bottom, similar to a cylinder, and is used more in the North American market. Double Doy pouch is very different from other packaging, it is easy to stand out and be chosen by consumers when placed on the shelf.

Perforation Pouch

Perforated pouch is a general term, the main sign is that there will be a hole left by the perforation in the seal of the bag. This hole will not affect the material in the bag, nor will it affect the use of the bag. In the process of shopping malls, this kind of hole is generally used for hanging, saving the space of the bag on the shelf.

Top Seal Pouch

As the name describes, the top seal pouch is a type of packaging bag that is sealed at the top of the packaging bag. Most of the stand-up pouches on the market are top seal pouches. The material in the bag is accumulated at the bottom of the bag, so the top seal pouch can make the bag stand more stable.

Therefore, the application of top seal pouches is still very wide, and consumers and manufacturers are more willing to choose top seal pouches.

Tear Notch Pouch

A tear mark refers to a gap in the seal of the package, which can be easily opened by the user. The range of tear notch pouches is very wide, as long as there is this gap in the package, it can be called a tear notch pouch.

Window Pouch

Ordinary premade pouches are completely sealed and opaque, and consumers cannot see the shape of the internal materials through the bag. In order to meet this demand of consumers, premade pouches with windows have been produced. Open a small opening on the ordinary prefabricated bag and supplement it with a transparent plastic film so that you can see the inside of the bag.

Bag Label Pouch

In order to make customers notice, and to increase product sales, promote the product, or for other purposes, manufacturers usually put a striking label on the bag of the product. Such a bag is a bag label pouch.

New types of bags are always produced in continuous updating. The selection of pouches needs to consider many factors, combine the characteristics of different materials and the sales effect that the seller wants to achieve, and then choose a suitable pouch type in order to achieve the fastest conversion of benefits.