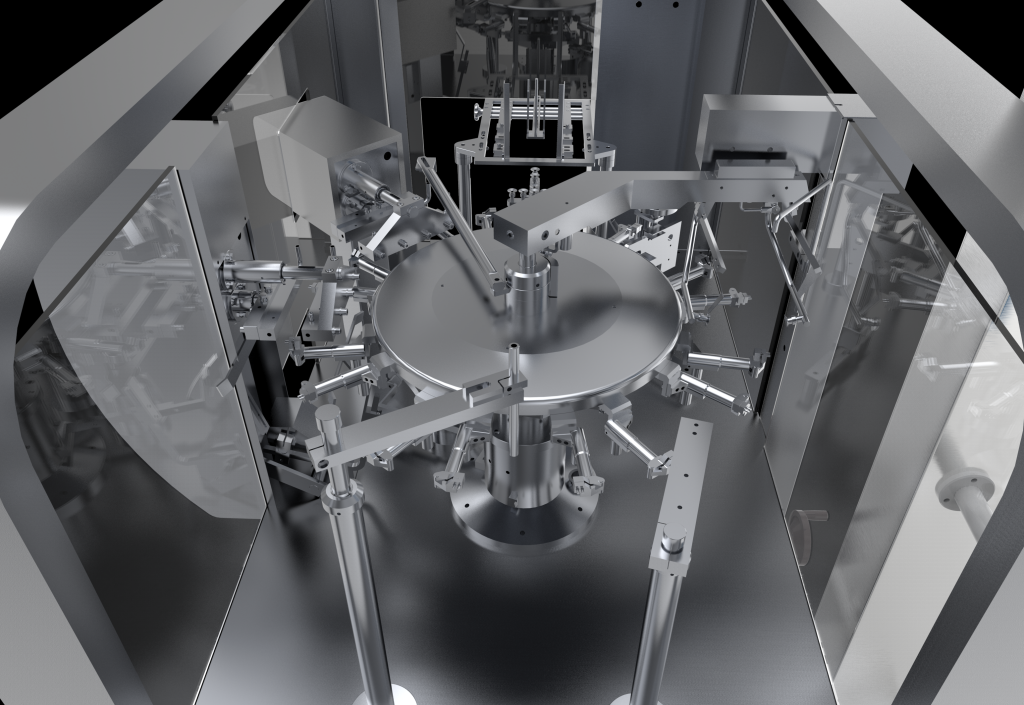

Automatic food packaging involves the use of automatic machinery for food material handling in the packaging process. Packaging food requires a safe and hygienic packaging environment. Efficiency and quality is also important when it comes to food packaging; hence, the need for automation in the food packaging process. Basically, automation is used in the food processing and packaging business because of the numerous advantages it offers. Automatic food packaging machinery is a good choice for your startup business because it can assist you in meeting and exceeding customer expectations. It can also efficiently perform a variety of operations in the exact requirements and ensure that the output is extremely professional in appearance. This will help elevate your new business to the next level in the eyes of your customers.

Automatic Food Packaging Machinery Options

Among so many considerations, the most important thing for your startup business may be the cost. So to get the most cost-effective options, we recommend choosing either the HFFS or VFFS packaging machine.

Horizontal form fill and seal machine (HFFS)

This horizontal form fill and seal machine is used majorly for solid products that can be introduced into a filling tube and from there placed into the formed film tube. The film is passed through a hollow former to make a tube. Once a product is forced into this tube, the spinning fin seal rollers will seal it almost immediately.

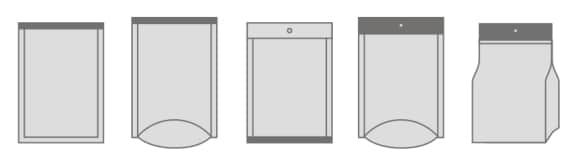

The HFFS machine manufactures a pillow pouch; although it can be modified to produce gusseted bags to fit larger products. Furthermore, HFFS machines could be equipped with drilling gear to make holes in the upper seam for products hanging on racks.

Instead of first delivering a single folded web and later a sealed web into an HFFS machine, two webs can be supplied to all four sides once the product is introduced. With this technique, the packager can use webs made of two entirely different materials or webs made of the same material but with different designs.

Vertical form fill and seal machine (VFFS)

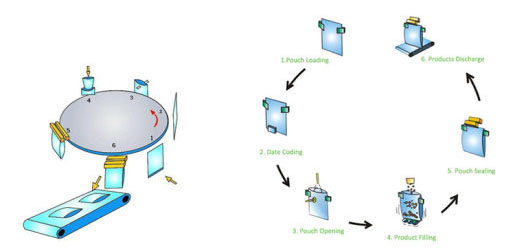

VFFS machines operate in three stages. The first makes pouches out of a web of flat heat seal component, fills them with the introduced products, and seals them all in a continuous process. These pouches can be used as the major package or inserted into cartons to provide an additional layer for safety during transportation and storage.

The bars that make up the cross-seals in most VFFS machines are made of a Nichrome wire that acts as a conductor for electric current to pass through and heat the bar to the required temperature. This temperature and the time duration must be carefully monitored. This is done to provide heat at an optimal temperature sufficient enough to heat up the plastic without burning it up. This is necessary to mitigate overheating, which could cause the film to wrinkle and subsequently burn through.

Similarities between the HFFS and VFFS machines

- Both machines are good for the production of healthy food and can be used in the medicine industry

- Both machines have operations that form the pouch shape.

- Both machines are with functions of forming, filling and sealing; with the functions all in one machine.

- Materials used in producing these machines are the same.

Differences between the HFFS and VFFS machines

| HFFS | VFFS |

| Horizontal operation | Vertical operation |

| Requires more floor area | Requires less floor area |

| More expensive | Cheaper |

| Higher production speeds | Lower production speeds |

| Better finish and bag quality | Good finish and bag quality |

| Different types of filling system on a machine | Single type of filling system on a machine |

| Forms more complex bags | Forms simple bags |

| Ideal for solid food products | Ideal for granulated/powdered products |

Factors to Consider When Choosing Automatic Food Packaging Machinery for Your Startup Business

Undoubtedly, automatic packaging machines are great. However, in selecting the best option for your startup business, there are certain factors you must put into consideration.

Type of product

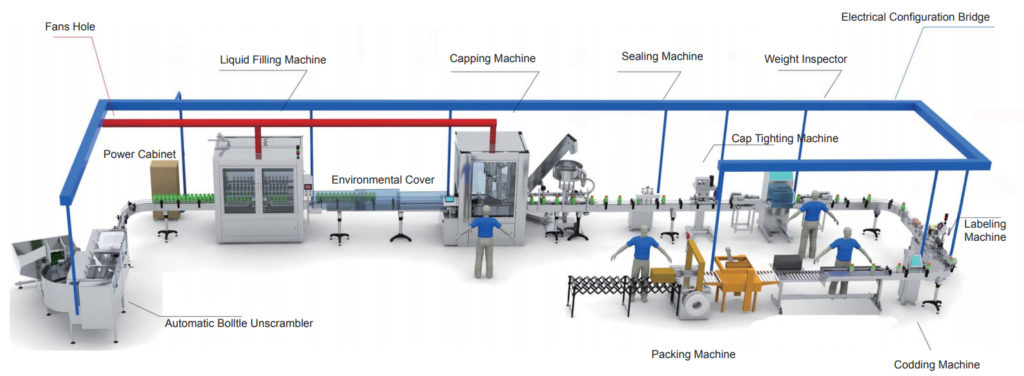

The packaging machines you’ll need are largely determined by the kind of food product you intend to package. For example, a beverage company will use different packaging machinery as compared to the solid food industry.

Speed

Very high-speed machinery, as one might expect, can increase production rates while also increasing expenses. To fulfill your demand estimates, select a food packaging machine that can create the required output.

Budget

There are some high-end machines with advanced sensors that eliminate the need to bother about any aspect of the packaging process regardless of the volume of output. There are also less expensive machines that can only perform certain parts of the process for you. Some might only be able to package few products. Choose a packaging machine that is most cost-effective for you.

Energy use

When estimating the cost of packaging, some manufacturers overlook the cost of power. When you use a machine that consumes a lot of power, the electricity cost might constitute a significant portion of the packaging cost – it could even surpass the cost of the machine itself.

Size

Make sure the packaging machinery you’re getting fits within your production space by checking the dimensions carefully.

Maintenance

Regular maintenance of packaging machinery will result in not just repair expenses but also losses associated with production disruption. Therefore choose packaging machinery that would require less maintenance and exhibit excellent after-sales service.

Carbon footprint

Food companies are striving to go green by adopting production methods that are environmentally friendly. You can ensure that your packaging machine has the lowest carbon impact possible by reducing inefficient procedures and maximizing recycling,

Conclusion

To determine which automatic food packaging machinery is best for you, you need to first consider the type of product you want to package. Thereafter, other considerations can follow as explained above. After you have determined what type of machine you need, you will need to contact manufacturers that can provide you with more enlightenment. Contact us today for more information about automatic food packaging machinery.